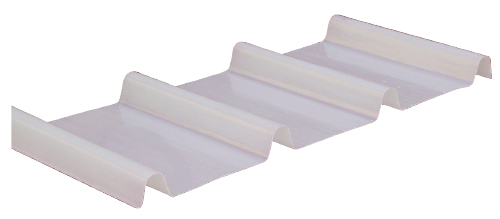

Polycarb / Fibreglass & Twin Wall

Zammit Metal Roofing, supply a large range of domestic and industrial fibreglass and Polycarbonate sheeting to meet all building requirements. Our high-quality materials are designed to be durable and reliable, ensuring superior performance for your projects. With our professional team of experts, you can be assured that you will receive the best advice and guidance on your roofing needs.